Low Pressure Plasma Systems

Low Pressure Plasma Systems are specialized vacuum system components designed, assembled and operated for the specific process of producing plasma chemistry safely and repeatedly.

Request A QuoteLow Pressure Plasma Systems are specialized vacuum system components designed, assembled and operated for the specific process of producing plasma chemistry safely and repeatedly.

Request A QuoteThese Low Pressure Plasma Systems offer a wide range of options for surface modification. Some examples of this would be fine-cleaning of contaminated components, plasma activation of plastic parts, etching of organic or inorganic materials, plasma deposition, low friction coating, and coating of plastic parts with PTFE-like layers (polytetrafluoroethylene). Low Pressure Plasma Systems are used in a great variety of industries when it comes to combining materials or changing the surface characteristics of industrial materials.

With low pressure plasma systems, plasma is generated in an evacuated chamber containing a metered or dosed amount of the desired precursor gas or gases. This gas is then excited to change state to a plasma. One of the examples of this excitement would be to pass a radio frequency current through the gas. This RF energy creates a conforming gas plasma that comes in contact with the material surfaces inside the vacuum chamber. Two or more steps can be conducted successively, such as surface cleaning and surface coating, or cleaning, etching, and activating due to advances in plasma system control software.

Low pressure plasma systems are often operated in batch mode, which is ideal for production processing, product testing, and research.

Request A Low Pressure Plasma Quotation

Low-pressure plasma systems have the ability to perform cleaning, activation, etching and coating treatments. These treatments can optimize a surface for its designated manufacturing task.

For more than 30 years, we've acquired relevant experience with Low Pressure Plasma Systems to become a technology leader in the implementation and use of low pressures plasma systems.

Low pressure plasma systems come in different sizes with different characteristics. Thierry offers Low pressure plasma systems that come in entry-level, production and industrial classes.

Control Cabinet:

W 310 mm H 330 mm D 420 mm

Chamber:

Ø 3.9 in, L 10.9 in

Chamber Volume:

2

Gas Supply:

1 gas channel via needle valve

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Semi-Automatic

Control Cabinet:

W 560 mm H 600 mm D 600 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

2 gas channel via needle valve

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Semi-Automatic

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber:

W 12" x H 11.8" x D 14.6"

Chamber Volume:

30

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Touch Screen

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber Volume:

15

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

575

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

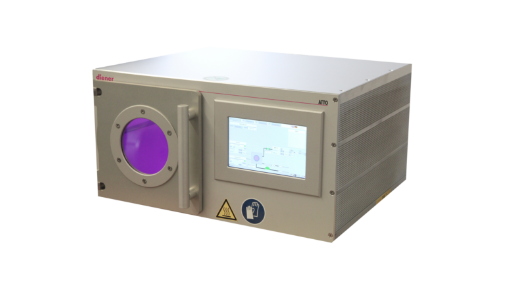

W 425 mm H 275 mm D 450 mm

Chamber:

Ø 8.3 in, L 11.8 in

Chamber Volume:

10.5

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz)

Control:

Touch Screen

Control Cabinet:

W 870 mm, H (with feet) 1860 mm, D 1400 mm

Chamber:

∅ 640 mm, D 1000 mm

Chamber Volume:

320

Gas Supply:

2 - 6 MFCs

Generator:

80 kHz - 300 Watt

(13.56 MHz)

Control:

PC