Plasma Treatment Articles

Plasma Coating

|

2 min read

Manufacturers often want to plasma coat their components and products to improve the performance and reliability of the end product. Plasma coating or plasma enhanced chemical vapor deposition are a core technology that can enable product improvements in performance and reliability. The application of plasma coating in a line of products will enhance product performance and can enable a completely new line of products not previously possible. Learn more about the application of plasma coating in this article

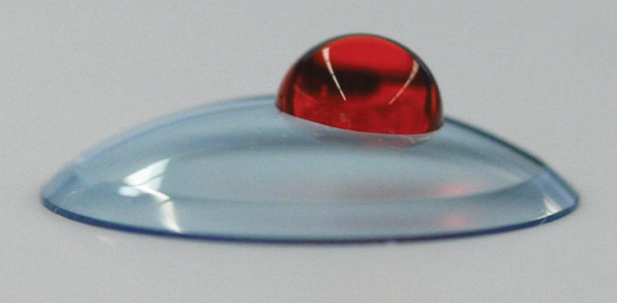

Plasma coating is using low pressure plasma or atmospheric plasma to apply a film of approximately 10 nm to 10 microns of coating to a base material with good adhesion. This thin film application will produce a drastic change in the chemical and physical performance of the part. By optimizing the properties of the surface independently from the base material, the performance characteristics can be improved and optimized from the performance of the base material alone.

Plasma spray coating works by injecting monomer or gas feedstocks into an atmospheric plasma system to produce an atomized stream of material. The stream that originates from the nozzle of the plasma system is filled with molecular components that will bond together on the surface of the base material to produce a solid coating. This coating procedure is done at atmospheric pressure without the use of a vacuum system and produces repeatable results.

Plasma spray coating works by injecting monomer or gas feedstocks into an atmospheric plasma system to produce an atomized stream of material. The stream that originates from the nozzle of the plasma system is filled with molecular components that will bond together on the surface of the base material to produce a solid coating. This coating procedure is done at atmospheric pressure without the use of a vacuum system and produces repeatable results.

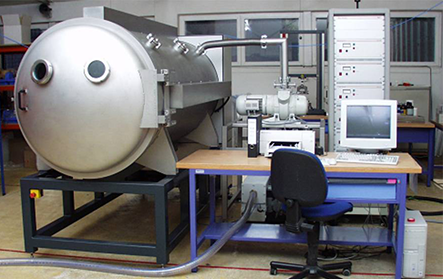

Plasma vacuum coating works by injecting a monomer or gas feedstocks into a plasma vacuum source. Chemical feedstocks are arranged to produce a specific chemical deposition or coating. The coatings that are applied via plasma vacuum can be performed in very small thicknesses and with the right control system the coating will be very uniform and very repeatable. This method of plasma processing separates the operator from the chemistry resulting in very good industrial hygiene and is the preferred method for many manufacturers.

There are many different types of coatings that can be applied to parts. A few examples would include:

There are many different types of coatings that can be applied to parts. A few examples would include:

Plasma coating is an efficient and high-performing method of enhancing the materials of a manufacturing component to improve its applicability and capability. Plasma coating opens new doors for manufacturing of products and enables new product innovations. Only by understanding how plasma coating or plasma enhanced chemical vapor deposition works can manufacturers and product development engineers conceive new products that were thought not possible before. Plasma coatings can not only improve the aspects of a material but can change the surface properties entirely as well.

Interested in learning more about how coatings enable manufacturers to improve the quality of their products? Please consider downloading our eBook titled "The Manufacturer's Plasma Coating Playbook" to learn about coating applications. If you are interested in speaking to an expert in plasma applications, please consider reaching out and scheduling a plasma treatment overview discussion.

Comments