Plasma treatment creates the ideal surface cleanliness conditions for adhesive bonding to be consistently strong and reliable. Using plasma treatment, a two-step process that cleans and activates surfaces, manufacturers can now meet product reliability and safety requirements.

Benefits of using plasma treatment:

Plasma Cleaning is a dry method of cleaning that turns foreign materials into a gas, thus removing molecular-level contamination residues from a surface.

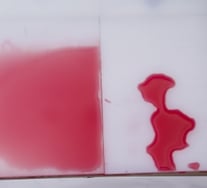

Plasma Activation modifies surfaces on a molecular level to change the wettability, or surface energy. Wettability refers to the effect of a liquid to stay in contact a surface. Plasma activation enables surfaces to better maintain contact to the adhesive, resulting in high quality adhesion performance.

email: plasma@thierry-corp.com | phone: +1 (248) 549-4581

The process of using plasma to clean and activate a surface prior to applying an adhesive or coating to increase adhesion is a great way to improve the strength of the bond.

The process of using plasma to clean and activate a surface prior to applying an adhesive or coating to increase adhesion is a great way to improve the strength of the bond.

Microscopic contaminations not visible to the naked eye are found on all surfaces. Almost always, these contaminants must be removed as a first step to producing high-performance adhesion between surfaces when working in the application of gluing, printing, painting, bonding, or coating.

Plasma activation significantly increases the reliability and performance of a product. This increase in reliability leads to a decrease in scrap and cost of manufacturing in a production value stream. This is why plasma activation is an important part of manufacturing where a bonding process is incorporated in building a product

Low Pressure

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

Atmospheric Pressure

These systems apply air or gas plasma to a small area of a part without treating the entire part.

Custom Industrial

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

Vacuum Chambers

Many manufacturing processes require high altitude testing or material drying vacuum chamber solutions.

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system, we guide them with plasma process development to ensure their success. Contract service is also an available service option.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com