This technology is used in fuel production, gas scrubbing to reduce harmful emissions, and bulk surface activation for large surface areas or continuous processes.

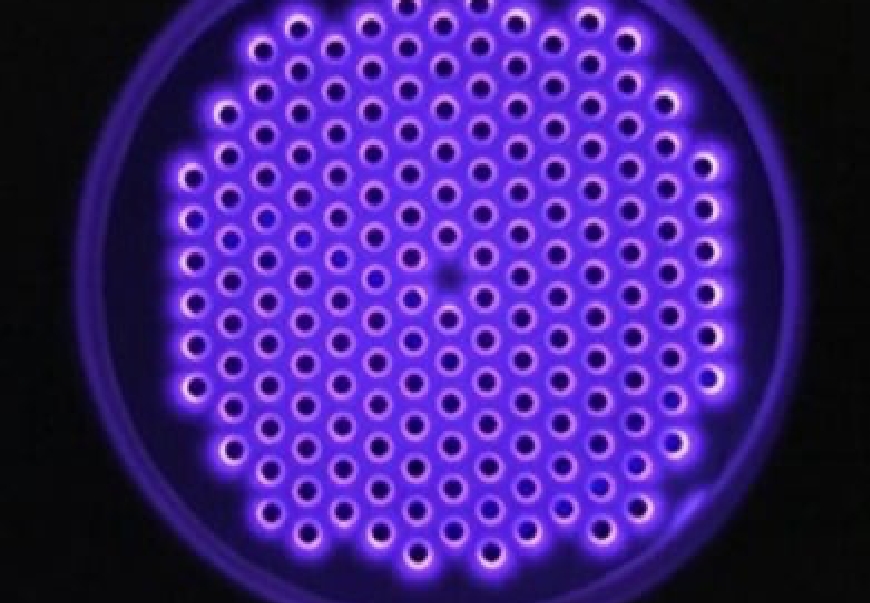

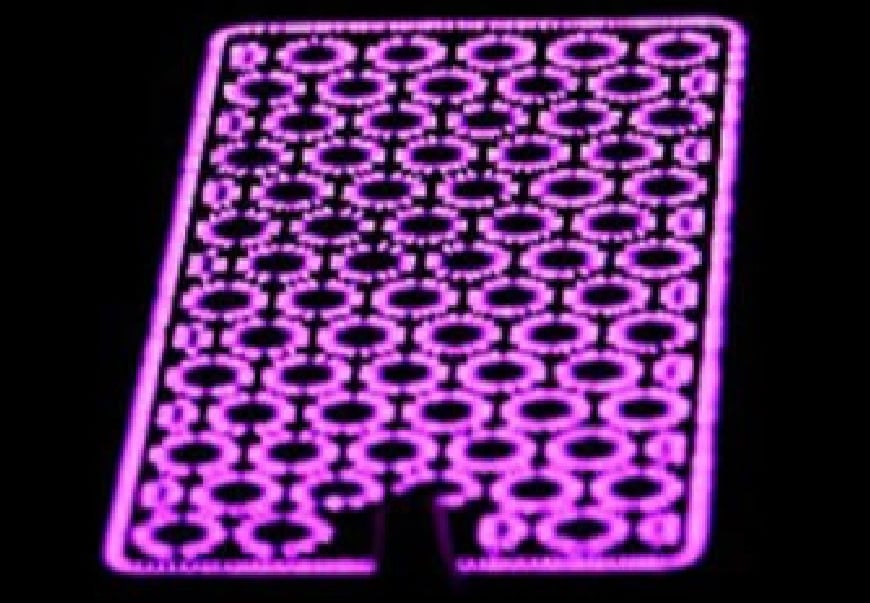

Plasma is produced by two electrodes with a dielectric between these electrodes to limit the current flow in the plasma. This low-density plasma can be described as Dielectric Barrier Discharge (DBD).

This method of plasma production is also called silent discharge due to the current limiting dielectric controlling the rate of ionization of the gas. This relatively low-density plasma produces controlled ionization of the available gas generating little to no detectable sound. This method of low-level density plasma production is useful in gas plasma processing like ozone generation, gas reforming, and broad area low-level activation processes.

The gaseous monomers are introduced directly into the plasma jet by means of a carrier gas. Therefore, the plasma focuses on the monomer on the surface and polymerizes it.

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

These systems apply air or gas plasma to a small area of a part without treating the entire part.

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

Many manufacturing processes require high altitude testing or material drying vacuum chamber solutions.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com