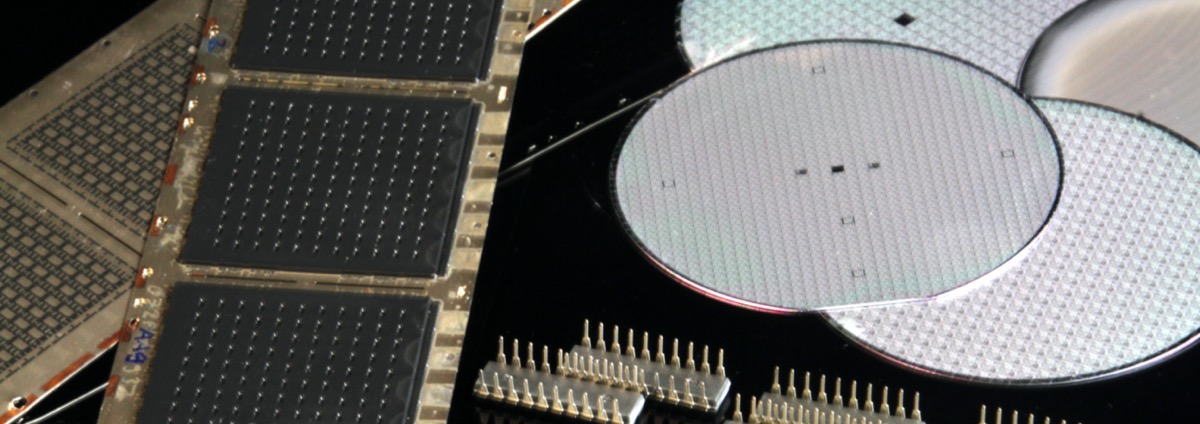

Thierry's low-pressure plasma systems offer a wide range of options for surface modification like:

email: plasma@thierry-corp.com | phone: +1 (248) 549-4581

Request a Discovery Call Today!

We'll help you choose the correct plasma system for your specific application.

Our plasma treatment experts will:

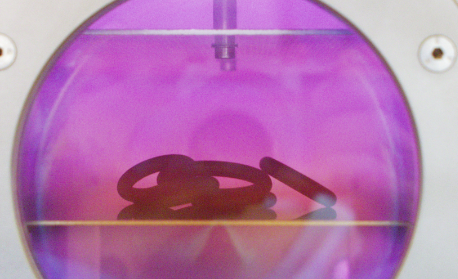

With low-pressure plasma systems, plasma is generated in an evacuated chamber containing a metered or dosed amount of the desired precursor gas or gases. This gas is then excited to change its state to a plasma. One of the examples of this excitement would be passing a radiofrequency current through the gas. This RF energy creates a conforming gas plasma that comes in contact with the material surfaces inside the vacuum chamber. Two or more steps can be conducted successively, such as surface cleaning and surface coating, or cleaning, etching, and activating due to advances in plasma system control software.

With low-pressure plasma systems, plasma is generated in an evacuated chamber containing a metered or dosed amount of the desired precursor gas or gases. This gas is then excited to change its state to a plasma. One of the examples of this excitement would be passing a radiofrequency current through the gas. This RF energy creates a conforming gas plasma that comes in contact with the material surfaces inside the vacuum chamber. Two or more steps can be conducted successively, such as surface cleaning and surface coating, or cleaning, etching, and activating due to advances in plasma system control software.

Low-pressure plasma systems are often operated in batch mode, which is ideal for production processing, product testing, and research.

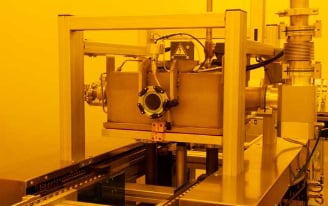

Low Pressure

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

Atmospheric Pressure

These systems apply air or gas plasma to a small area of a part without treating the entire part.

Custom Industrial

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

Vacuum Chambers

Many manufacturing processes require high altitude testing or material drying vacuum chamber solutions.

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system, we guide them with plasma process development to ensure their success. Contract service is also an available service option.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com