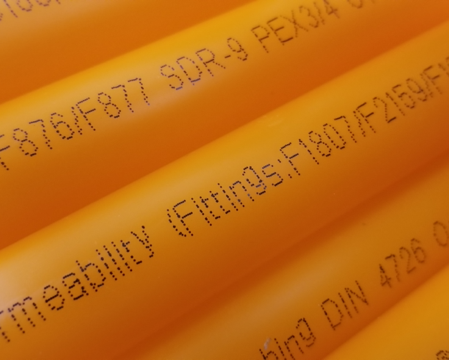

Achieving reliable, high-quality painting and printing can be challenging. Adhesion performance requires thorough control of the material surface that is receiving the ink or paint.

Plasma surface cleaning and activation provides the control that is required to eliminate scrap and rework due to print and paint adhesion failure.

Find out how you can guarantee durable, high-quality printing and painting applications with plasma treatment.

email: plasma@thierry-corp.com | phone: +1 (248) 549-4581

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system we guide them with plasma process development to ensure their success. Contract service is also an available service option.