For more than 30 years, we’ve acquired relevant experience to become a technology leader in the implementation and use of plasma systems for manufacturers & university research. We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers.

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

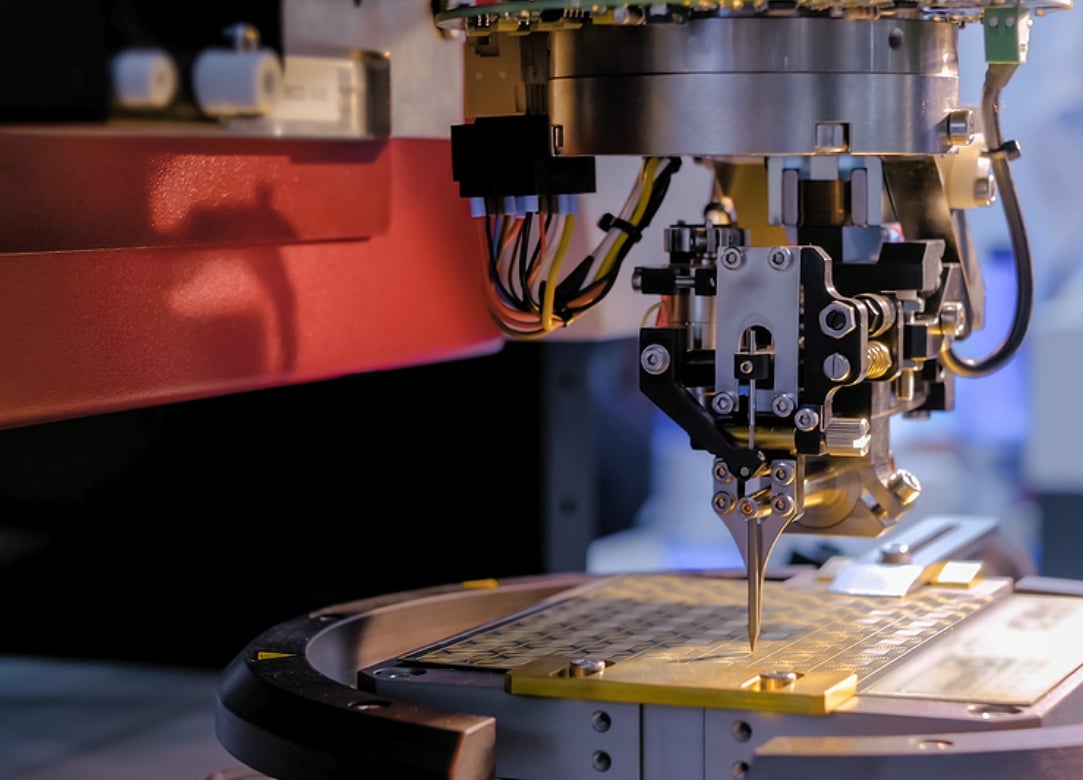

These systems apply air or gas plasma to a small area of a part without treating the entire part.

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

Many manufacturing processes require high altitude testing or material drying vacuum chamber solutions.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com