How do you know if your plasma treatment was carried out correctly?

The answer is: With our plasma indicators. They are the perfect tool to improve your plasma-related processes – no matter if you are applying plasma at low or atmospheric pressure!

We at Thierry Corp. always strive to make monitoring your plasma processes as easy and cost-effective as possible. Our plasma indicators can verify if your plasma treatment was successful quickly and reliably.

Sometimes a plasma treatment is completed and the obtained surface looks neat and tidy to the naked eye but later it turns out that something went wrong during the process. This is not only annoying but it also can be very costly. Plasma indicators can be used to avoid such an undesired outcome.

They instantly show you if your surface activation, cleaning, or etching has been successful or not.

Our novel plasma indicators can be used for low-pressure plasma processes that require high purity and cleanliness. They are based on glass substrates to avoid any outgassing in such critical processes from the indicator itself. Due to this high standard of clean processing, our plasma indicators are a superior solution for plasma applications in the healthcare or semiconductor field.

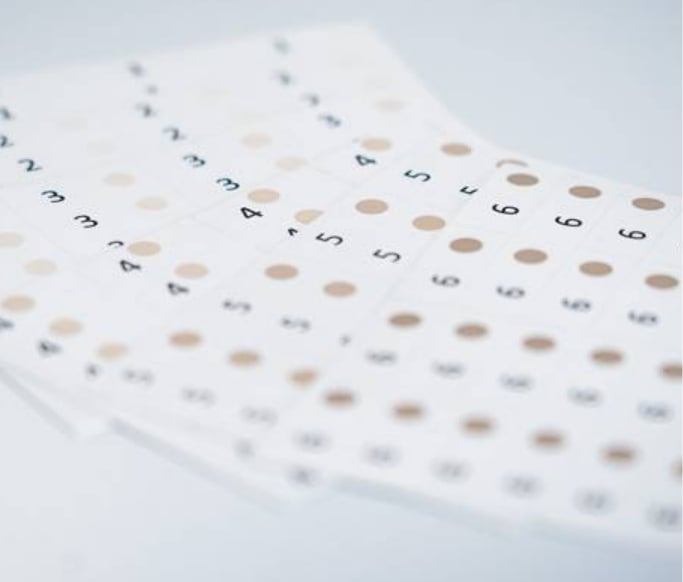

The dark dot in the center of the indicator vanishes completely when the plasma process has been carried out correctly. This holds for all kinds of common surface treatments such as activation, cleaning and etching.

Our atmospheric pressure indicators are specially coated labels that can be attached directly to the workpiece. The coating consists of a special fabric, which will simply dissolve when the plasma process was successful.

This allows checking the treatment quality with the bare eye instead of with costly technical equipment. You will immediately see if your surface treatment conforms to your specifications.

Our indicators for atmospheric and low-pressure plasmas are suited for activation, cleaning and etching.

Our plasma indicators can be used in all kinds of plasma surface treatment processes, such as activation, cleaning, or etching.

They are suited for plasma systems in atmospheric and low-pressure environments.

Yes, the glass indicators are perfectly suited for such processes (e. g. in medical or semiconductor processing).

The dark dot is, in fact, the real indication that the process was carried out successfully. If it has completely vanished after the plasma treatment, everything is alright. If it is still there If it is still there (even if the color changes), the process has to be repeated.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com