Accurately measuring the surface energy of your workpiece is critical for reliable manufacturing and surface engineering. Thierry Corp’s surface energy measurement tools provide fast analysis of key surface parameters, including adhesion and wettability. Use them immediately after treatments such as plasma cleaning or etching, and before downstream steps like coating, bonding, painting, or sealing to ensure consistent, high-performance results.

Material surfaces are constantly changing, which can lead to degradation and reduced product performance. Our handheld surface energy measurement tool helps you prevent this. It is simple to operate and captures critical surface parameters in seconds, enabling you to build a reliable digital thread of your surface preparation process. With this data, you can reduce waste, save time and costs, and optimize each production step.

Improve your surface engineering and track critical surface properties over time with a simple, handheld digital inspection device. Our surface energy measurement tool delivers fast, accurate readings on virtually any surface at the push of a button. It can be used on small parts, tubes, edges, and even in deep, narrow trenches on your workpieces, making it easy to verify and document surface conditions wherever you need them.

Thierry Corp’s surface energy measurement tool offers a variety of novel features that make this device an indispensable asset for surface treatment and engineering.

The inspection head is engineered for demanding industrial environments while maintaining maximum measurement accuracy. It can be configured and exchanged to match your specific application requirements, however specialized they may be. We offer custom inspection heads for edge analysis, narrow channels, tubes, small surfaces, and other challenging geometries. Integrated status lights, control buttons, and audio signals enable true one‑handed operation, so operators can inspect surfaces without needing to look at the display.

The measurement device includes a quick-start test plan tailored to your process, along with integrated analytics software for fast, reliable surface evaluation. The measurement head can read QR codes to document each production step and reduce human error. The system also offers advanced user management with individual user profiles and automatic activity logging, so settings cannot be changed accidentally. Measured data can be exported via Ethernet API or RS232.

Our patented measurement principle deposits a small fluid droplet onto the surface and then analyzes its contact angle from a top-down view. Because this method is highly precise, it allows contact angle measurements to move from the lab directly into production environments. The Lucent lighting system provides controlled, uniform illumination on any surface, even when roughness or reflectivity varies. This reduces setup time and operator effort while delivering highly accurate, repeatable results.

Users with admin rights can define custom surface profiles with specific inspection parameters. This improves measurement accuracy on surfaces with highly variable textures, roughness, or surface treatments.

The dynamic detection mode factors in how the droplet interacts with the surface. As a result, the contact angle measurement becomes significantly more precise than standard goniometer measurements in the lab.

In addition, the wetting analytics feature tracks dynamic droplet deformation. This reveals the presence, amount, and uniformity of water-soluble chemicals on the surface. These data give immediate insight into hydrophilic substances and other unwanted contaminants, such as detergents, on the workpiece.

Our surface measurement software includes a pass/fail mode with fully adjustable tolerances. When this mode is active, the operator sees whether a surface has passed or failed, making inspections faster and easier.

In addition, a near-failure alert notifies the operator when a surface is approaching the failure limit or tolerance. In this case, the pass/fail indicator turns yellow to clearly highlight that the surface is close to failing.

Since all surfaces are different as they may be flat, rough, cracked, convex, concave, or entirely regular, measuring the surface parameters is often challenging. Thierry Corp’s surface energy measurement device overcomes these challenges with our custom tailored solutions.

Quality check station: We can also provide a check station to securely hold the handheld device, the specimen, or both in place. All check stations connect via RS232 and Ethernet API for easy integration into your process.

Wearable sling: The wearable sling allows operators to move freely with the device while keeping both hands available for handling parts and fixtures.

Extended tether: When a greater distance is required between the main unit and the measurement point—for example, on large or hard-to-reach surfaces—we offer an extended tether of up to 6 meters. This extended tether can be combined with a fixed station for the handheld device to support flexible, ergonomic operation.

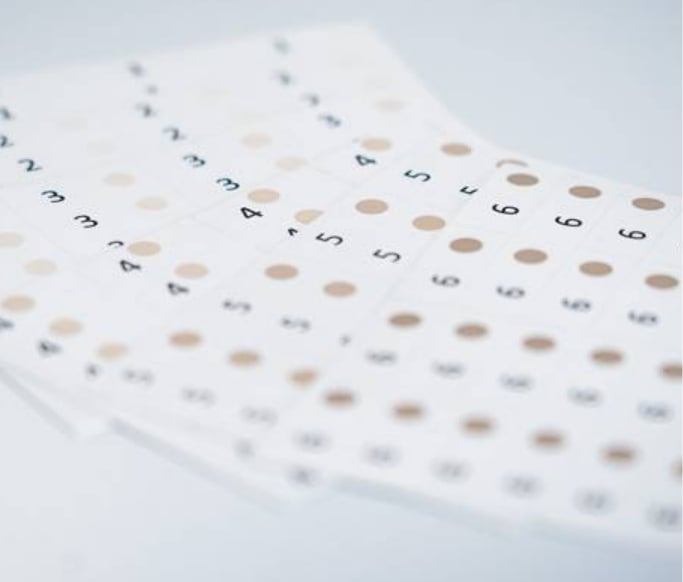

Our tool deposits a tiny water droplet onto a surface and measures the contact angle. This gives very accurate information about the surface characteristics, such as cleanliness, adhesion properties, or chemical composition. The surface energy measurement device works with a patented ballistic deposition technology, that is highly sensitive to the smallest changes in the surface properties.

While standard goniometers measure with a side-view on a water droplet, the surface energy measurement tool from Thierry Corp. is based on top-down imaging. This enables the measurement of curved, rough, or dented surfaces, even on small samples. Our device can measure on tools, PCB boards, pipes, etc. Another important difference is that a side-view can only obtain two contact angles but in real-world applications, a water droplet never remains in a perfectly round shape. The top-down approach can take up to 200 measurement points around the whole water droplet. Thus, it is far more accurate than a standard goniometer.

The surface energy measurement tool measures different surface types with ease. Some examples are polymers, metals, semiconductors, composites, electronic circuit boards, glass and many more. The device gives quick insights into surface properties, such as chemical composition, homogeneity, or the quality of surface treatment processes.

In a standard side-view goniometer, the surface roughness can be a serious issue because it can obscure the view onto the edge of the droplet. However, with our top-down measurement, the entire droplet is measured without any annoying interference from the surface roughness.

Our surface energy measurement device is calibrated to the same precision as a NIST-traceable standard goniometer. However, in real-world measurements, the accuracy of our tool has been proven to be far better than comparable standard instruments. If the surface is chemically uniform, the deviation of the contact angle measurements is less than one degree.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com