Plasma coating or plasma enhanced chemical vapor deposition (PECVD) is an application using plasma in order to modify the properties of materials to produce a coating on a surface. Ultra-thin layers of different molecular groups or monomers are applied on objects and surfaces. With the help of this plasma coating process, surfaces can be made hydrophobic or hydrophilic, scratch resistant, corrosion protected or functionalized to enable bonding. Another modern form of plasm coating is the so-called plasma spray deposition technology. In contrast to PECVD, where surface temperatures on the substrate are normally close to room temperature, plasma spraying operates with a high-velocity, high-temperature thermal plasma that has temperatures of up to 10,000 K. Thus, the coating material is quickly molten and accelerated towards the work piece, where it forms rather thick layered depositions.

For coating with low-pressure plasma, a gas or liquid monomer vapor is introduced into the plasma chamber. This process gas or vapor is molecularly bonded with the aid of the plasma. This coating is deposited in the range of 10s of angstroms to microns depending on the process parameters.

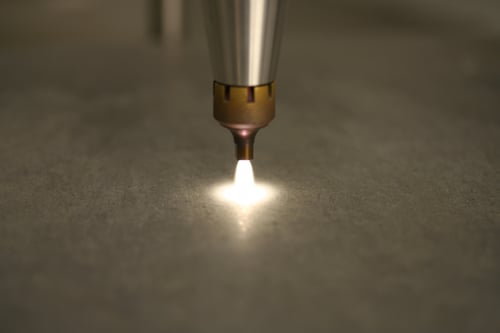

For coating with an atmospheric plasma process, the gaseous monomers are introduced directly into the plasma jet by means of a carrier gas. Thus, the plasma focusses the monomer on the surface and polymerises it. A special variety of plasma jets is the thermal spray technology, which is often used for metal or ceramic coatings. These depositions are important for heat or wear resistant materials.

Both, high and low temperature plasma coating techniques can be applied with non-thermal or thermal plasmas, depending on the coating material, the desired thickness and, of course, the heat resistance of the substrate. With different plasma coating methods nearly all industrially relevant coatings can be obtained.

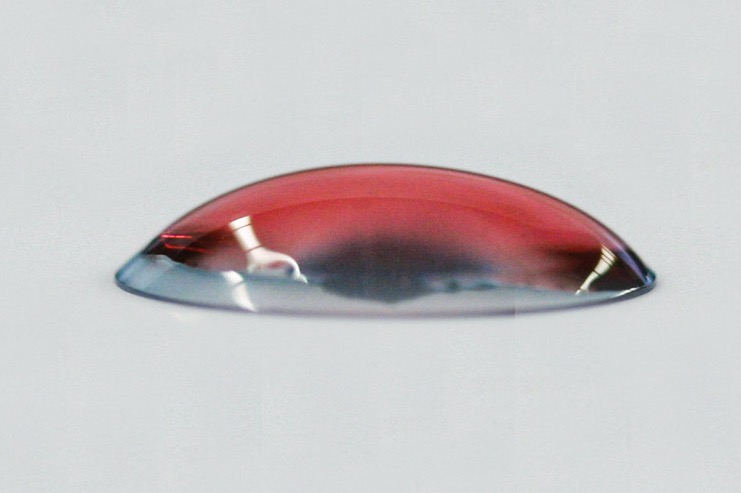

The process of producing a plasma-enhanced chemical vapor deposition coating using HMDSO as a feedstock can produce a hydrophobic coating. This process of producing a hydrophobic coating or a polymer like coating using HMDSO is possible by limiting or eliminating the amount of oxygen used in the process gases at the time of deposition. The absence of oxygen in the process produces a coating with a polymer like performance. Adding oxygen to the process in higher concentrations produces a hydrophilic coating higher in oxide concentration. As the process gas concentration increases in oxygen concentration, the deposition produced becomes less organic and higher in silicon oxide concentration.

The process of producing a plasma-enhanced chemical vapor deposition coating using fluorine monomer gases as a feedstock can produce a PTFE-like hydrophobic coating. There are many fluorine-containing monomer gases optimized for plasma feedstocks. These optimizations in coating performance can vary widely based on the application or industry requirements. Examples of some of the optimizations would include contact angle, mechanical wear performance, electrical conductivity, thermal conductivity, biocompatibility, water-resistance, or chemical resistance.

The process of producing a plasma-enhanced chemical vapor deposition coating using the unstable monomer vinyl acetate gas as a feedstock can produce a polyvinyl acetate (PVA) like hydrophilic coating. PVA is used in adhesives, adhesive tape, sausage casings, cheese rinds, and carpet coatings because it is harmless. The process of producing a hydrophobic coating or a polymer like coating using HMDSO is possible by limiting or eliminating the amount of oxygen used in the process gases at the time of deposition. The absence of oxygen in the process produces a coating with polymer-like hydrophobic performance. As the process gas concentration decreases in oxygen concentration, the deposition produced becomes more organic and polymer-like.

The process of producing a plasma-enhanced chemical vapor deposition coating to decrease the coefficient of friction on a surface is possible with plasma processing. This reduction of surface friction can be made with PTFE like, HMDSO and carbon plasma deposited treatments. The process of using carbon as a low friction coating is the lowest cost of these coatings. This simple, low-cost process is often used in coating elastomeric seals and O-rings to produce a condition where these components are easier to handle, and vibratory bowl feed in high volume manufacturing. This method of using dry lubrication on seals also increases wear resistance and minimizes abrasion.

The process equipment used to produce an atmospheric plasma spray coating using a monomer vapor or gas as feedstock to produce a coating or deposition on different substrates is currently available. Atmospheric plasma spray coating equipment is affordable, easy to configure and easy to use. The ability to load monomer or gas feed stock of your choice into the atmospheric plasma source and consistently plasma spray a coating can be performed on a research or manufacturing basis. Good operational equipment efficiency, repeatability and reliability are possible with proven atmospheric plasma deposition tooling today.

Thermal spray (or flame spray) coating processes are usually operated at atmospheric pressure and with a high temperature plasma jet. A process gas such as argon or air reaches temperatures of 10,000 K or even higher. Due to these extraordinary process conditions, this technology is commonly used to deposit pure metals, alloys, ceramics or combinations of those materials. This is also one of the oldest plasma spray coating technologies. It is based on an electric arc, which is burning between an anode and a cathode. This arc evaporates a wire or part of the electrodes, which is then blown out of the arc with high velocity and immediately deposited on the substrate.

Suspension Plasma Spray Coating is a special form of plasma spray coating in which a mostly ceramic feedstock in a liquid dispersion is fed into the plasma jet. The small particles in the suspension are usually somewhere between 20 and 120 microns in diameter. These small particles are rapidly molten and accelerated onto the treated surface, where they form a homogeneous coating.

Industrial manufacturing is a leader in the application of plasma enhanced chemical vapor deposition (PECVD). Using PECVD to produce a coating to permanently change surface energy in materials, apply low friction coatings, or coat a material to enhance the performance or properties of materials. In combination with spray coating, plasma assisted deposition methods are used in most modern industry branches. Here are a few prominent examples:

Medical device manufacturing has used PECVD as a way to produce changes in material performance. Plasma Enhanced Chemical Vapor Deposition PECVD for functionalization, coating, or surface augmentation is also possible with plasma processing. Preparing the surface of an implantable device for cellular growth or providing an intermediate layer to promote better coating adhesion are typical applications. Plasma processing provides repeatable, stable, controlled processes for medical manufacturing applications. There is also the possibility of depositing bioactive materials, which hinder or prevent the growth of viruses, bacteria or other germs. This can be of special importance for surfaces in hospitals, surgery tools or bandage materials.

Automotive and Aerospace industry: Whenever it comes to wear resistance or friction reduction there is a plasma coating process that can help. PECVD is mostly used for hard films such as diamond or diamond like carbon (DLC), which are also suitable for corrosion protection or for improving abrasion properties.

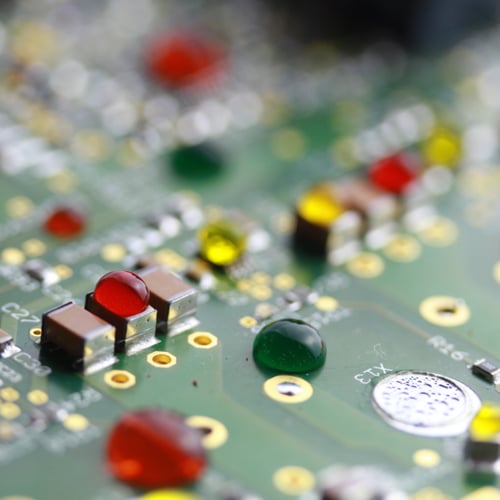

High power electronics and Semiconductor industry: Again, PECVD coatings of DLC, doped diamond, silicon carbide are widely used in these industry areas. Furthermore, plasma spraying can create semiconducting coatings of high purity, such as aluminium oxide (Al2O3), yttria (Y2O3) or dense FeCrMoCBY films.

Optics: High-tech, custom tailored optical films attract larger and larger attention. In this field PECVD processes are the workhorse that is used to deposit films with different optical properties. These films can be mono- or multi-layered, they can have graded refractive indexes or nanostructured surfaces. Interesting materials for optics are fused silica, diamond or zirconia. The components that are produced with such coatings can be, for example: optical filters, antireflective glasses, optical waveguides and many more.

Solar Industry: Plasma deposition is rather common in the solar industry, especially when it comes to photovoltaics (PV). However, in addition to the more traditional coating technologies, such as PECVD for antireflective SiO2 deposition on PV modules, novel technologies are emerging. Examples are the deposition of materials for low cost PV materials with non-thermal atmospheric pressure plasma or highly porous ITO coatings that are produced by suspension plasma spraying.

Textile Industry: Since the textile industry needs high throughput on large areas, the most common plasma coating procedures in this industry are low pressure roll-to-roll plasma sources. Usually plasma coatings in this area are used to create hydrophobic or even superhydrophobic textile surfaces as well as to increase the adhesion of color on cloth.

Toolmaking Industry: If hard tools like drills, cutting blades, etc. are needed, PECVD coatings do much of the heavy lifting. The coatings in question are either diamond, DLC, tungsten carbide or different forms of metal nitrides, which are used to harden the surface of power tools or machine parts or give those parts greater wear resistance.

Control Cabinet:

W 560 mm H 600 mm D 600 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Touch Screen

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber Volume:

120

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 870 mm H 1860 mm D 1400 mm

Chamber Volume:

375

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

7500

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

When a plasma spraying process is applied a fine powder, wire, liquid or suspension is fed into the flame that emanates from a plasma jet. The temperature of this flame is up to several 10,000 K and the particle velocities start from about 150 m/s. Hence, the dispersed material is rapidly heated and accelerated towards a substrate. Due to the high temperature and velocity, the material quickly melts and forms flat droplets on the surface until a relatively thick coating is formed. This technology is perfectly suited for the deposition of high temperature materials such as molybdenum, tungsten carbide, TSA or ceramics.

As the name suggests, air plasma spray processes work at ambient pressure and use air as carrier gas for plasma ignition. Small particles of the coating material are molten in the thermal plasma flame and rapidly form coatings on different surfaces. This process is very repeatable and can be used for different types of depositions, ranging from metals and carbides to ceramics and mixtures of those.

Plasma spray coating can be used for a large variety of substrates and coating materials. Important examples are corrosion or wear protection but also high end materials for thermal insulation are commonly deposited. It is especially attractive for metal or metal-ceramic hybrid coatings because the thermal plasma jet melts the feed material and rapidly covers the surface of the substrate with layered depositions.

Creating nano- or microstructures with plasma is an increasingly important topic in different industrial fields. There are plenty of options for obtaining nano coatings with plasma. Most of them involve PECVD techniques but in recent years, also conventional or even liquid plasma spray coating processes have been utilized for this purpose. Most nano coatings are either based on ceramic materials or carbon depositions.

TSA stands for Thermally Sprayed Aluminum and is a type of coating, which is usually used for corrosion protection coatings on various shapes. Although the abbreviation only refers to aluminum, this plasma spraying method is also applied to zinc or mixtures of those two metals. TSA can also be found in high temperature applications, where parts have to withstand up to 750 K – for example in aerospace or submarines.