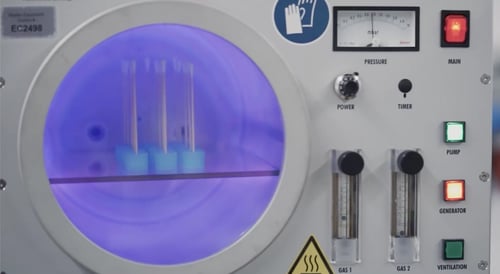

Plasma-enhanced chemical vapor deposition (PECVD) allows the creation of highly uniform thin layers, promotes purity and adhesion, and varies compositions on substrates of different materials and geometries. Due to its versatility and efficiency, as well as the possibility of manufacturing processes employed in large scale, this plasma coating technique has found applications in many different industries. For example, in the optics industry it is used in manufacturing optical filters, anti-reflective films, and devices with an undesired refractive index. In mechanical engineering it is used to increase tool life by applying wear resistant coatings (e.g., diamond-like carbon or quasi-diamond) or preventing corrosion (e.g., Cr2O3 or MgO). In electronics and microelectronics it is used to provide an insulating (e.g., SiO2), semiconductive (e.g., Si or GaAs ) or conductive (e.g. of Al or SiCr) coating for parts or devices, and in the production of solar cells for surface passivation.

PECVD Efficiency

Depositing a film on a substrate to obtain special properties may be performed by PECVD, in which the gas mixture or desired coating substances are activated by applying a voltage that becomes a reactive plasma species (ions, electrons, radicals, atoms and molecules). This PECVD procedure allows the reaction to take place at lower temperatures (approximately 100-400 °C) than heat-activated CVD, which makes it particularly useful when the substrate cannot withstand high temperatures. Furthermore, increasing the plasma density also increases the concentration of reactive species and consequently the reaction rate. Increasing the density of plasma can also work at lower pressures, resulting in greater control over the directionality of the ions. All this contributes to making PECVD plasma coating flexible, efficient, and suitable for countless applications.