The application of plasma etching a material with gas plasma is a very unique process that converts a solid to a gas form for removal. Plasma etching can eliminate the need for chemical etching which is time-consuming and uses volatile organic compounds (VOC) and other dangerous chemicals. Organic materials, inorganic materials, and polymers are easily etched with non-corrosive oxygen plasma. More complex inorganic materials such as silicon and metals are etched with CF4 plasma or plasma of a similar gas mixture. This also shows the high degree of flexibility of plasma etching. There are only a few gases commonly used for plasma etching, namely argon, hydrogen, oxygen and some fluorine compounds (or mixtures of those, respectively). With these easy-to-obtain gases nearly every industrially relevant surface can be etched. It does not matter if the material to be etched is a metal, a polymer, ceramics, glass or any other silicon-based compound. Plasma etching does the job in any case.

Plasma etching is the process of converting a solid directly to a gas in a low-pressure plasma system by bombarding a given surface with excited or ionized particles. This gas is then pumped out of the vacuum chamber at a controlled rate to optimize uniformity and other process parameters. The entire process of etching is performed without the material ever coming in contact with a fluid. Hence, this plasma surface treatment technology offers superior controllability compared to wet chemical processes. It is also possible to remove only very thin layers from a surface, down to some nanometres thickness. This is commonly used in etching machines in the microelectronics and semiconductor industry, where small scales and thin layers are of utmost importance.

The process of etching a polymer, organic substance or hydrocarbon-based solid works well with an oxygen-based plasma process. This oxygen-based plasma etches these materials by combining the carbon and hydrogen in the molecular structure with oxygen from the plasma. This produces CO and HO in combination with short molecular chains that remain in a gas state and are easily pumped out of the chamber as a gas. Oxygen plasma etching can also be applied as a surface treatment that enhances the wettability of polymers or alters their surface roughness. It can also be used to treat silicon or silicon nitride surfaces, which are oxidized in the process and form a nanometre thick layer of silicon oxide on top of the surface.

The process of plasma etching to reduce an oxide on the surface of a metal or in a bulk oxide state is etched with a hydrogen-based gas or gas mixture. Similarly, this plasma etching process uses hydrogen to combine with the oxygen on the surface and produce HO and other variants of the bulk molecular structure into a gas that is pumped out of the vacuum system. Besides the removal of oxides from surfaces, selective hydrogen plasma etching of sp2 bonded carbon is believed to be one of the most important processes of diamond layer deposition. Researchers also have found out that the influence of hydrogen ions is far more important in the etching process than the influence of hydrogen atoms or molecules, which also makes a point in favor of hydrogen plasma etching.

The process of plasma etching a surface using argon is a physical etching method versus the chemical etching method described above. In this method of plasma etching, the energy of the heavy argon atom in the plasma is very high. This high level of energy enables the individual argon atom to deliver more energy to the surface of the part breaking the molecular bonds of the surface material. The result is that these surface material atoms or short molecular components, are etched or ejected into the plasma for removal. Argon plasma etching is widely used on polymer substrates such as polyethylene, where it can lead to an enhanced wettability of the surface.

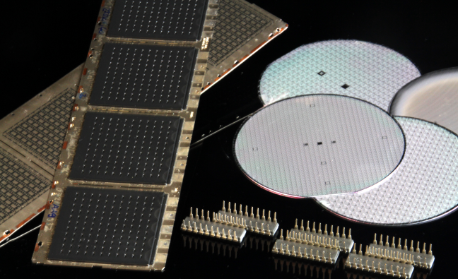

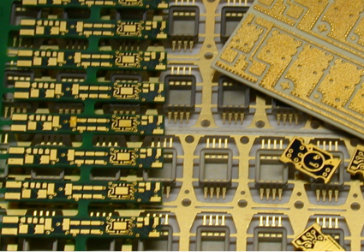

The process of plasma etching a material with a robust molecular structure or complex composition like metals and chemically stable polymers is done with a corrosive gas-based component. This corrosive gas of choice often focuses on fluorine-based chemistry like CF4, SF6, or other similar gases. The addition of these kinds of corrosive components provides a method of converting additional chemistries into a gas state providing a method of plasma etching. This technology can be used for the cleaning of large surfaces, such as silicon wafers, or the removal of polymer debris on printed circuit boards (PCBs). Since the whole process takes place in a vacuum chamber, it is also much easier to collect the corrosive gas after the process and minimalize the environmental impact of this etching technology.

Reactive ion etching (RIE) is a plasma etching process that adds a charge to the part being etched which induces a directional component to the etching process. This directionality of the etch enables significantly smaller etch feature sizes, which are commonly used in the semiconductor industry. This plasma surface treatment option is mostly used to get rid of contaminants or other depositions on silicon wafers. A common RIE system consists of a vacuum chamber with a high-frequency plasma source (13.56 MHz are normally used) into which the etching gas is introduced. The wafer is placed at the bottom of the chamber and hit by the reactive ions that are mostly fluorine-based. The RIE technology is, for example, used for the production of large area silicon solar cells.

Control Cabinet:

W 310 mm H 330 mm D 420 mm

Chamber:

Ø 3.9 in, L 10.9 in

Chamber Volume:

2

Gas Supply:

1 gas channel via needle valve

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Semi-Automatic

Control Cabinet:

W 560 mm H 600 mm D 600 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Touch Screen

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber Volume:

15

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

500

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

8000

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

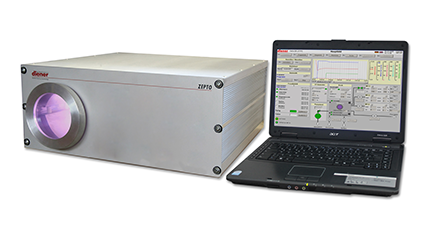

Control Cabinet:

W 425 mm H 185 mm D 450 mm

Chamber:

Ø 4.1 in, L 11.8 in

Chamber Volume:

2.6

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz)

Control:

External PC

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com