Plasma Treatment Articles

Plasma Cleaning,

Plasma Etching

|

2 min read

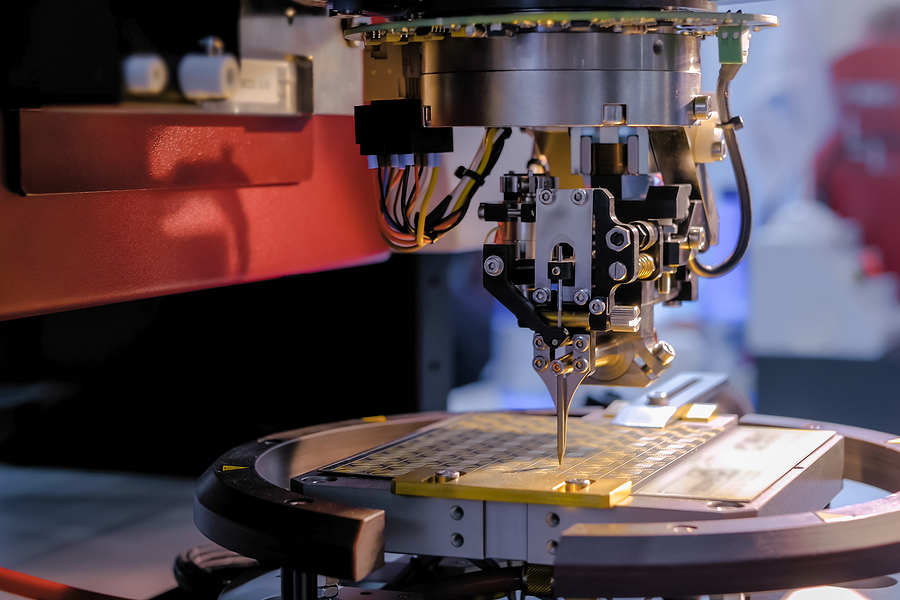

It can often be a challenge to increase the reliability of ball and wedge bonds. Improved reliability can be achieved by reducing the oxide on bond pads to create more reliable electromechanical connection in devices. Plasma treating the device before bonding can reduce the oxide and foreign material. This treatment minimizes the growth rate of oxide after treatment, which will increase the shelf life of parts.

Bond pads can be difficult to bond to because they often are contaminated with foreign material or oxide on the metal. This foreign material or oxide can create nucleation sites in the weld nugget or bond material, which significantly weakens a bond. These nucleation sites can lead to cracking or fracturing of the weld nugget or shifting conductivity.

![]() Plasma treatment can enable a more reliable electromechanical connection in a manufacturer's device by reducing the oxide in bond pads and lead frames. Reliable connections are essential so that the device performs as designed and limits device failures. Removing the oxides can often be challenging if not done correctly and can even grow after cleaning if the proper procedures aren't taken.

Plasma treatment can enable a more reliable electromechanical connection in a manufacturer's device by reducing the oxide in bond pads and lead frames. Reliable connections are essential so that the device performs as designed and limits device failures. Removing the oxides can often be challenging if not done correctly and can even grow after cleaning if the proper procedures aren't taken.

Plasma treating the device before bonding is a great solution to increase ball and wedge bonds' reliability. This treatment will minimize the growth rate of the oxide after treatment.

The most reliable approach for cleaning these bonds is plasma etching in a vacuum chamber with Hydrogen or other oxide reducing gas. This plasma etching method is the standard in the semiconductor industry today. When manufacturers don't understand the bond issue, there typically are many failures, which can be a very costly manufacturing issue.

![]() Plasma treatment has excellent variability in treatment size. Plasma can treat one part at a time or scale up to an extensive batch treatment with a large plasma etching system. In these larger systems, the process controls are very repeatable and automated. These process controls allow for repeatability where all the parameters are the same, and each device receives the same treatment.

Plasma treatment has excellent variability in treatment size. Plasma can treat one part at a time or scale up to an extensive batch treatment with a large plasma etching system. In these larger systems, the process controls are very repeatable and automated. These process controls allow for repeatability where all the parameters are the same, and each device receives the same treatment.

Lead frames can challenge other cleaning processes as they are often loaded in cassettes that are the standard for production. Plasma cleaning can be achieved while the lead frames are still loaded in these cassettes, making for easy loading and unloading to optimize a manufacturing process without wasted time.

Plasma etching and cleaning is the most reliable way to prepare lead frames and bond pads for manufacturing. Plasma treatments allow manufacturers to eliminate possible contamination and have trust that the bond pads will have a clean surface for bonding after treatment.

To learn more about plasma treatment, etching and cleaning to improve reliability of ball and wedge bonds for electronics manufacturers, please read our article titled "Plasma Etching and Cleaning Strategy for Better Product Quality."

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com

Comments