Plasma Treatment Articles

Plasma Activation,

Plasma Cleaning

|

2 min read

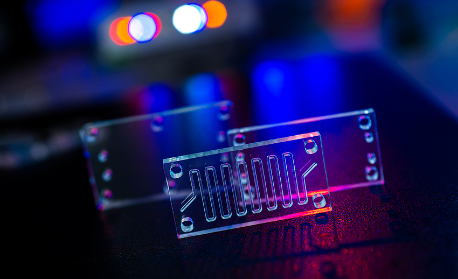

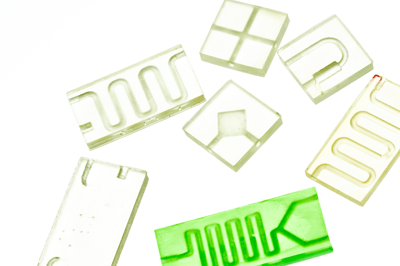

Many manufacturers ask the question of how to clean PDMS when producing a microfluidic device. Whenever PDMS, polydimethylsiloxane, needs to be cleaned, it is generally due to poor incorporation of the catalyst or the introduction of foreign material. Poor incorporation of mixing the catalyst and its residues will result in poor surface quality as well. It is always recommended that the user establish the right manufacturing processes and methods to eliminate the need to clean PDMS components.

If there is a need for PDMS to be cleaned, steps must be taken to determine the root cause and eliminate this need for cleaning. Some issues that can be considered include a clean area where mixing is to be performed and where samples are handled and stored. If your mixing area is not clean, it should be moved to either a clean room, clean micro-environment, or fume hood. After the PDMS samples are created, they need to be stored in a sealed container where particles cannot accumulate on the surface.

If there is a need for PDMS to be cleaned, steps must be taken to determine the root cause and eliminate this need for cleaning. Some issues that can be considered include a clean area where mixing is to be performed and where samples are handled and stored. If your mixing area is not clean, it should be moved to either a clean room, clean micro-environment, or fume hood. After the PDMS samples are created, they need to be stored in a sealed container where particles cannot accumulate on the surface.

If there is poor incorporation of mixing of catalyst and its residues will result in poor surface quality. It is possible to clean the catalyst off by a plasma treatment which will volatilize that surface residue. Thus, a plasma cleaning treatment can address this issue, but it is always better to improve the mixing process to ensure a quality PDMS part is consistently produced.

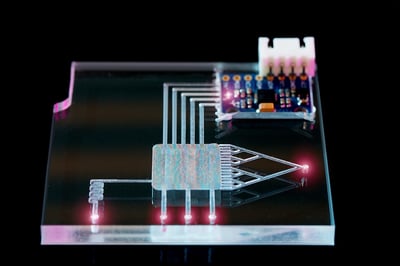

When creating PDMS samples, they may be dirty without the manufacturer even knowing it. For example, using a vacuum pump that uses PFPE based lubricant, like Krytox or Fomblin, can create molecular contamination in your vacuum chamber or tooling that can inhibit covalent bonding of PDMS to another silicon-containing surface for microfluidic manufacturing. Therefore, to create a microfluidic device, vacuum pumps containing PFPE should not be used. Instead, an oxygen service dry pump or a oxygen service pump that uses mineral oil is recommended for low-pressure plasma activation of microfluidic devices.

If contamination is particulate, then the particulates can be lifted off the surface using an ordinary adhesive tape if it is an adhesive that does not transfer residue to contact surfaces. This is not an ideal solution but will work for some applications. The best course of action is to identify the root cause of your particulate contamination and eliminate it from your process. This will ensure that the surface of your PDMS is contamination-free and increase the bond strength and burst pressure in your microfluidic device.

It is also essential that your activated surfaces (PDMS and silicon-containing surfaces) are only mated once. Touching them together or aligning them in contact can create a condition that could be diagnosed as surface contamination that leads to insufficient bond strength and burst pressure. It is best to establish a precise assembly process to ensure proper alignment between your two materials so that multiple contact applications do not occur.

It is also essential that your activated surfaces (PDMS and silicon-containing surfaces) are only mated once. Touching them together or aligning them in contact can create a condition that could be diagnosed as surface contamination that leads to insufficient bond strength and burst pressure. It is best to establish a precise assembly process to ensure proper alignment between your two materials so that multiple contact applications do not occur.

Whatever materials are used to make PDMS, the producer should ensure that the tooling used is clean before mixing your base material and catalyst. Plasma cleaning your mold or mixing container and other tools is a great way to ensure everything is clean before mixing, casting, or storing PDMS microfluidic components. Plasma treatment should only be used as a final cleaning procedure after a more rough or robust cleaning process.

Whenever possible, it is crucial to create a manufacturing environment and process that does not require cleaning PDMS and mating materials after production. If there is a situation where it is necessary to clean PDMS components, there are some tips and suggestions in this article to aid in the cleaning process. It is important to remember that your best option for PDMS production is to start clean and stay clean throughout your entire process.

To learn more about the best practices for plasma cleaning of PDMS, please read our eBook titled "How to Improve Burst Pressure and Yield in Microfluidic Devices."

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com

Comments