Plasma Treatment Articles

Plasma Activation,

Plasma Treatment

|

2 min read

Topic:

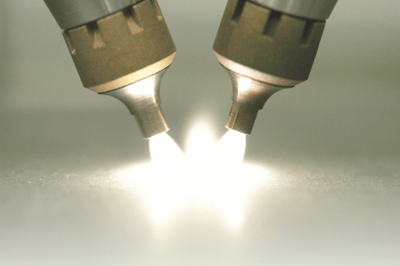

Many manufacturers have an issue with trying to increase surface energy by using a flame treatment. The flame treatment process can cause manufacturers to create scrap in a processing line. Scrap can be very harmful in the manufacturing process because it causes the material to be lost, leading to a loss in profits.

Flame treatment can create residual materials on the surface of parts which can mimic high surface energy without providing high surface energy. Low surface energy will result in poor bonding between the part and subsequent bond. When flame treatment first begins, it will start to improve surface energy. However, with continued treatment, it will create carbon on the surface, which will inhibit bonding.

Plasma treatment is a great alternative and replacement for flame treatment applications. Plasma activation eliminates the adverse side effects that flame treatment produces. The adhesion after the plasma treatment is also greatly improved. Another great plasma processing attribute is that a plasma process may be repeated without damaging the treated material. Flame treatment will continually wear on the surface of a material, causing extensive damage over time.

Plasma treatment is a great alternative and replacement for flame treatment applications. Plasma activation eliminates the adverse side effects that flame treatment produces. The adhesion after the plasma treatment is also greatly improved. Another great plasma processing attribute is that a plasma process may be repeated without damaging the treated material. Flame treatment will continually wear on the surface of a material, causing extensive damage over time.

Flame treatment on a surface that requires uniform treatment can be quite challenging. Often, surfaces need a uniform treatment across the entire surface to be appropriately bonded. Treating with a flame can result in overlapping or non-uniformity of the treatment, damaging the surface, and creating a very poor bond. In contrast, a low-pressure plasma treatment will create a clean, activated surface that is completely uniform and ideal for bonding after treatment.

When using a flame treatment in manufacturing, it can be quite dangerous. There is an issue with the flame treatment causing an ignition. If there is a source of flammable material in the manufacturing line where there is an ignition source, this can cause a hazardous effect because there are flammable materials in the area. This dangerous risk is a very high safety issue to the line itself and any personnel working there. These types of safety hazards should be minimized wherever possible in a working environment. Plasma systems do not have these risks.

One of the most common applications for flame treatment is for the treatment of coolers. Flame treatment is used on the outer material to prepare the ink to adhere to the surface. This manufacturing method is a low-cost step but can still be very dangerous. This simple process can also be achieved using a plasma system treatment without the risk of workers' danger.

Flame treatment applications often attempt to raise the surface energy of a material. They will shift the surface energy but at a very low level. Plasma treatment will result in a very high shift in surface energy if the correct process parameters are chosen. A higher-quality product should be the goal when manufacturing products.

Plasma activation is a better approach to solving a surface preparation issue in manufacturing or research. Manufacturing processes that use flame treatment should seriously consider switching to plasma processing as it is a safer, more effective solution. Plasma treatment reduces the risk of danger, is environmentally friendly, and produces higher surface energy with higher quality products than flame treatment. Many manufacturers and researchers are already switching and creating better outcomes with the aid of plasma system technology.

Plasma activation is a better approach to solving a surface preparation issue in manufacturing or research. Manufacturing processes that use flame treatment should seriously consider switching to plasma processing as it is a safer, more effective solution. Plasma treatment reduces the risk of danger, is environmentally friendly, and produces higher surface energy with higher quality products than flame treatment. Many manufacturers and researchers are already switching and creating better outcomes with the aid of plasma system technology.

To learn more about the benefits of plasma activation as an alternative to flame treatment in the manufacturing process, please read our article titled "Manufacturer’s Surface Activation Guide for Improved Adhesion."

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com

Comments